Page 108 - index

P. 108

Bio-Pharmaceutical Fittings (BPE)

Technical Specific tions

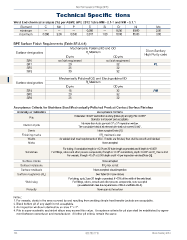

Weld End chemical analysis (%) per ASME BPE 2012 Table MM - 2.1-1 and MM - 5.1.1

Element C Mn P S Si Cr Ni Mo

minimum --- --- --- 0.005 --- 16.00 10.00 2.00

maximum 0.030 2.00 0.045 0.017 1.00 18.00 15.00 3.00

BPE Surface Finish Requirements (Table SF-2.4-1)

Mechanically Polished ID and OD

Dixon Sanitary

Surface designation R Maximum High Purity code

a

ID µ-in. OD µ-in

SF0 no fnish requirement no fnish requirement

SF1 20 32 PL

SF2 25 32

SF3 30 32

I Mechanically Polished OD and Electropolished ID

R Maximum

Surface designation

ID µ-in. a OD µ-in

SF4 15 32 PM

SF5 20 32

SF6 25 32

Acceptance Criteria for Stainless Steel Mechanically Polished Product Contact Surface Finishes

Anomaly or Indication Acceptance Criteria

If diameter <0.020" and bottom is shiny [Notes (2) and (4)]. Pits <0.003"

Pits

Diameter is irrelevant and acceptable.

No more than 4 pits per each ½" x ½" inspection window.

Cluster of pits The cumulative total of all relevant pits shall not exceed 0.040".

Dents None accepted [note (1)]

Finishing marks If R maximum is met

a

Welds As welded shall meet requirements of MJ-6. If welds are fnished, then shall be smooth and blended.

Nicks None accepted

For tubing, if cumulative length is <12.0" per 20' tube length or prorated and if depth is <0.003"

Scratches For fttings, valves and other process components, if length is <0.25" cumulatively, depth <0.003" and R max. is met.

a

For vessels, if length <0.50" at 0.003 depth and if <3 per inspection window [Note (3)].

Surface cracks None accepted

Surface inclusions If R max. is met

a

Surface residuals None accepted, visual inspection

Surface roughness (R ) See Table SF-3 (see above)

a

For tubing, up to 3 per 20' length or prorated, if <75% of the width of the weld bead.

Weld slag For fttings, valves, vessels and other process components, none accepted

(as welded shall meet the requirements of MJ-6 and Table MJ-3).

Porosity None open to the surface

Notes:

1. For vessels, dents in the area covered by and resulting from welding dimple heat transfer jackets are acceptable.

2. Black bottom pit of any depth is not acceptable.

3. An inspection window is defned as an area 4" x 4".

4. Pits in super-austenitic and nickel alloys may exceed this value. Acceptance criteria for pit size shall be established by agree-

ment between owner/user and manufacturer. All other pit criteria remain the same.

106 800.789.1718 Dixon Sanitary 2014