Page 302 - index

P. 302

Technical

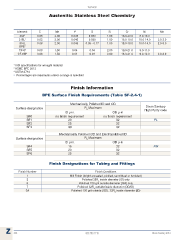

Austenitic Stainless Steel Chemistry

Element C Mn P S Si Cr Ni Mo

304 1 0.08 2.00 0.045 0.030 1.00 18.0-20.0 8.0-10.0

316L 1 0.03 2.00 0.045 0.030 1.00 16.0-18.0 10.0-14.0 2.0-3.0

316L 0.03 2.00 0.045 0.05 - 0.17 1.00 16.0-18.0 10.0-14.0 2.0-3.0

BPE 2

CF-8 3 0.08 1.50 0.04 0.04 2.00 18.0-21.0 8.0-11.0

CF-8M 3 0.08 1.50 0.04 0.04 2.00 18.0-21.0 9.0-12.0 2.0-3.0

1 AISI specifcations for wrought material

2 ASME BPE 2012

3 ASTM A743

• Percentages are maximums unless a range is specifed

Finish Information

BPE Surface Finish Requirements (Table SF-2.4-1)

Mechanically Polished ID and OD

Dixon Sanitary

Surface designation R Maximum High Purity code

a

ID µ-in. OD µ-in

SF0 no fnish requirement no fnish requirement

SF1 20 32 PL

SF2 25 32

SF3 30 32

Mechanically Polished OD and Electropolished ID

Surface designation R Maximum

a

ID µ-in. OD µ-in

SF4 15 32 PM

SF5 20 32

SF6 25 32

Finish Designations for Tubing and Fittings

Finish Number Finish Conditions

1 Mill Finish (bright annealed, pickled, sand blast or tumbled)

3 Polished 32R inside diameter (ID) only

a

5 Polished 150 grit outside diameter (OD) only

7 Polished 32R outside/inside diameter (OD/ID)

a

3A Polished 150 grit outside (OD), 32R inside diameter (ID)

a

Z 300 800.789.1718 Dixon Sanitary 2014