Page 280 - index

P. 280

Technical

Identifying Threads

It is important to identify the threads required before ordering couplings.

Identifying threads can sometimes be the most diffcult and frustrating part of coupling selection. However, without the right

combination of threads, you may not provide a functional or safe connection.

The diameters, threads per inch (TPI) and thread pitch, etc. are necessary to completely identify a thread. Ring, Plug and GO/

NOGO gauges are required to accurately gauge or identify threads. In the feld, in the absence of these gauges, thread leaf

gauges can be used to identify the Threads Per Inch (TPI) and the thread pitch. On threads you have determined to be straight

threads, a caliper can be used to measure the Outside Diameter of the Male (ODM) or the Inside Diameter of the Female

(IDF). A caliper can also be used to take measurements of tapered thread diameters. However, these are more diffcult to

defne because of the taper. Fortunately, there are few tapered threads to deal with and these can usually be identifed from the

nominal ODM and the TPI.

However, identifying the thread may not fully identify what is needed in a mating ftting. The application is the primary limiting

factor on the thread type used. Dixon offers products with a wide variety of threads used with hose, pipe and hydraulics.

When attempting to choose a ftting, it is always advisable to frst identify the thread to which it must connect. This may entail

checking with a ftting or equipment manufacturer.

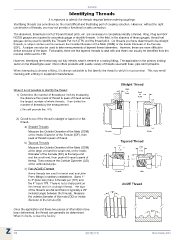

Straight Thread

When it is not possible to identify the thread:

1) Determine the number of threads per inch by measuring

the distance from peak of thread to peak of thread across

the largest number of whole threads. Then divide the

number of threads by the measurement

(This will provide the TPI).

2) Check to see if the thread is straight or tapered or fat

thread.

a) Straight Threads

Measure the Outside Diameter of the Male (ODM)

or the Inside Diameter of the Female (IDF), from

peak of thread to peak of thread.

b) Tapered Threads Tapered Thread

Measure the Outside Diameter of the Male (ODM)

at the large end and the small end, or the Inside

Diameter of the Female (IDF) at the large end

and the small end, from peak of thread to peak of

thread. Then measure the Outside Diameter (OD)

of the unthreaded pipe.

c) Flat (ACME) Threads

Acme threads are used for bevel seat and John

Perry fttings in sanitary installations. Sizes 1"

to 3" (tube size) have 8 threads per (TPI) and

the 4" has 6 TPI. There is not a sharp point on ACME Thread

this thread and it is a straight thread. The tops

of the threads are fat and there is typically a 29°

included angle between the threads. Measure 29°

the outside diameter of the male (OD) or inside

diameter of the female (ID)

Once the application and these two pieces of information have

been determined, the thread can generally be determined. 29°

When in doubt, contact the factory.

Z 278 800.789.1718 Dixon Sanitary 2014